- GENERATION 4.1

- Designed specifically for high current applications

- Reverse battery connection protection (no onboard fuse necessary)

- Market-leading, ultra-low on-state resistance

- Charges two batteries or banks from a single 300+ amp charging source independent of the main battery

- Ideal high current dual-diode configuration

- Allows independent discharge of each battery or bank

- User selectable Alternator excitation for ultimate installation flexibility

- Battery combine feature for self-jumping

- Extends battery life by insuring full charging voltage reaches the batteries

- 100% solid state, no moving parts to wear

- 99.9% efficient at maximum continuous current

- No heat sinks or airflow required

- No de-rating required over full temperature range

- Expansion port for external monitoring display (coming soon)

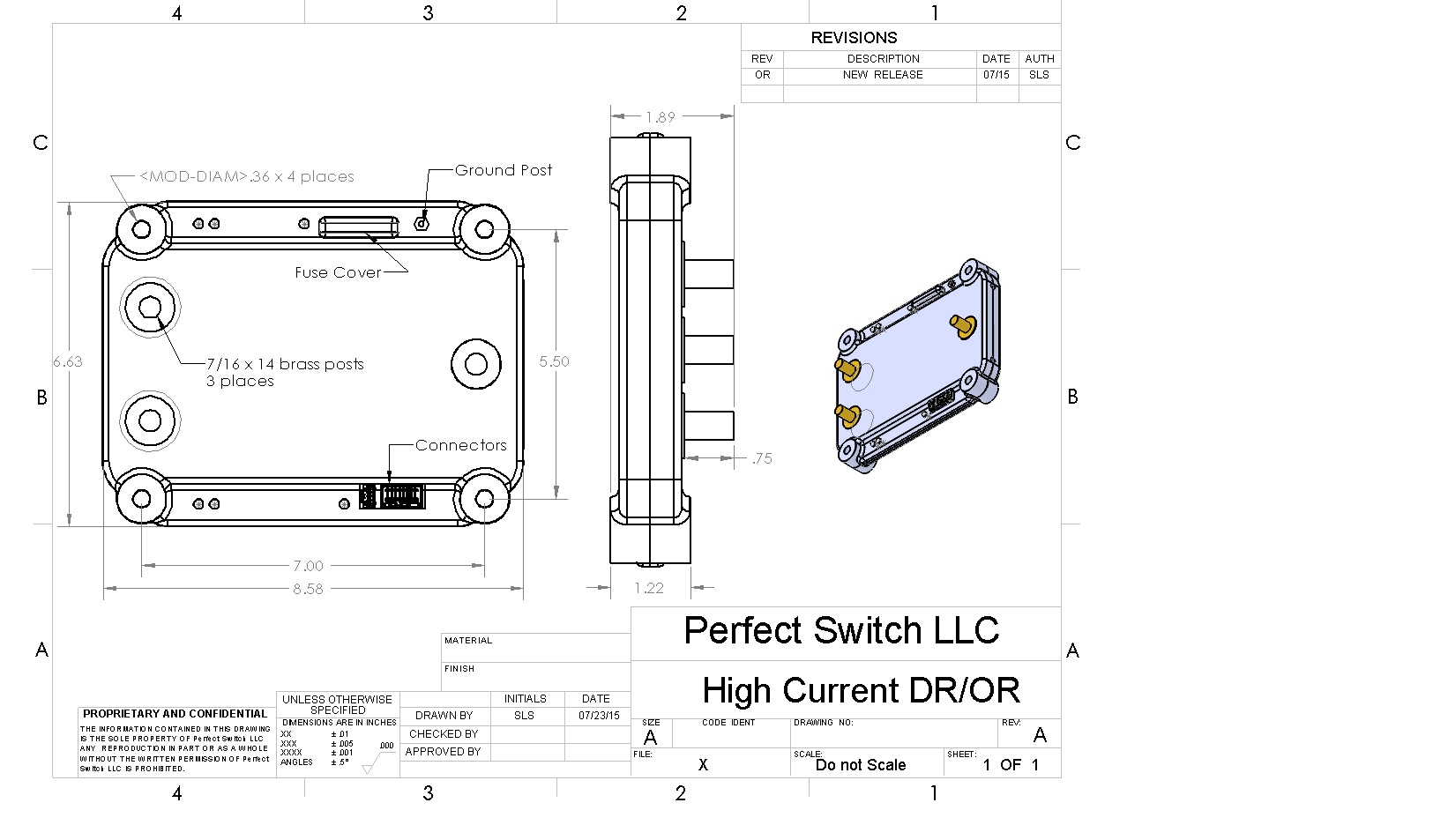

- Beefy 7/16-14 x .75″ brass connection posts for large lugs

- CNC cut and plated internal conductors optimized for high current transfer

- Hi-temp polycarbonate injection molded shell

- Dow Corning aero-qualified silicon potting

- Fully encapsulated rough-duty design

- Internationally patented MOSFET technology

- Recommended by top battery manufacturers

For industrial, military, marine, and custom automotive applications where currents often exceed 300 amps, we are proud to manufacture dual battery isolators capable of handling 400 amps, 500 amps, and 600 amps respectfully. We are a sole-source provider for solid-state, MOSFET based diodes capable of these elevated levels of current. A Dual Rectifier dual battery isolator has all the same outstanding performance characteristics of a single rectifier battery isolator, but provides discharge protection for two batteries; two, one-way electrical valves in a single package. DC currents will flow from the alternator to the batteries, but current will not flow between the batteries during discharge. Dual rectifier battery isolators are commonly deployed in dual battery configurations where each battery may be discharged independent of the other.

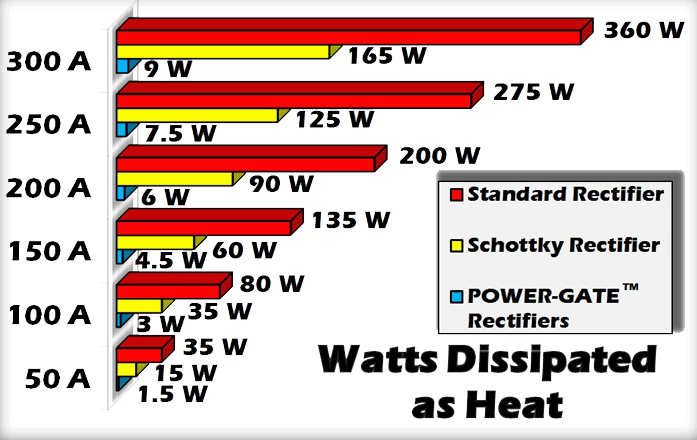

A common problem with conventional “marine” or “RV”; style isolators (aside from performance issues related to the obvious voltage drop and associated heat) is dealing with an internally regulated alternator. A dedicated excitation circuit ensures hassle-free integration with internally regulated alternators, “smart” regulators, and computer controlled alternators. Ultra-low on-resistance means devices require no heat-sinking and no airflow at currents up to 600 amps. Dual rectifier battery isolators are encapsulated in a custom polycarbonate enclosure and are well suited for hostile environments. POWER-GATE is recommended by top battery manufacturers to ensure that DC power gets to where it’s needed without the excessive heat, voltage loss, and amperage loss typified by more common, lesser performing silicon and Schottky devices built on large aluminum extrusions.

When the Battery Combine Feature is activated, the default isolation mode is temporarily overridden and both MOSFET arrays are forced into the energized mode. This causes the batteries to combine. For example, if the main starting battery is discharged to the point where the vehicle won’t crank, by pressing a mini logic-level momentary switch, the Battery Combine feature will enable the auxiliary battery to pass current to the main starting battery, at which point cranking can take place. Once the vehicle is started, release the momentary switch and POWER-GATE will default back to its full isolation mode.

Our high-current 400 amp, 500 amp, and 600 amp Dual Rectifier dual battery isolator devices are built in the Large package in order to accomodate large brass connection posts, large internal conductors, and the requisite number of semiconductors to handle full continuous current.

Need help configuring a Dual Rectifier? Click Here.

For OEM applications, military and fleet sales, special applications, or general questions call us 858.720.1339.